By David Lis | Wed, April 27, 22

Last winter, staff from NEEP’s Heating Electrification Initiative and staff from NYSERDA’s Clean Heating and Cooling teams realized we shared similar ideas about how we could enable better practices related to sizing and selecting air source heat pumps. With NYSERDA’s direct support, NEEP began working to realize these visions.

After about a year of conceptualizing, designing, and iterating, NEEP recently rolled out some exciting new functionality in NEEP’s cold climate ASHP product list website. The tools will assist ASHP designers and installers to more effectively size and select ASHP systems, particularly those that function in cold climates. A group of regional stakeholders worked together throughout the process to inform the development of the tools.

Since launching the ccASHP specification and product list in 2015, stakeholders have used it as both a qualified products list (QPL) and a tool to assist in sizing and selection. Products must meet certain technical requirements AND report a series of extended performance data for each system. Although the extended performance data has been leveraged by a savvy users, broad use of the data to inform system selection has been elusive. The new tools aim to make the data more accessible and actionable for the market to right-size systems.

| Information Overload | |

The Goldilocks Zone

This work supports the combination of factors that go into maximizing performance from ASHPs. In order to maximize performance of air source heat pumps, high performance systems must be both designed/sized well and installed well.

Variable capacity ASHPs with low temperature performance has opened up broad new markets for ASHPs, including regions like the Northeast. While variable capacity ASHPs are an amazing technology, today’s systems are not infinitely variable in their ability to modulate down to low delivered capacities…so sizing practices must evolve to account for a systems capability and the needs of particular applications.

Selecting a system that is “too big” for a particular application can lead to cycling which results in inefficiencies and discomfort when trying to cool. Selecting a system that is “too small” leads to insufficient heat which can obviously lead to discomfort of another kind (brrrrr). We’re looking for systems that avoid both of these issues and live most of their operational “lives” in the Goldilocks zone.

New Functions and Features

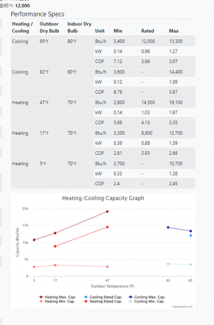

There are couple different new functions that can be accessed through the product list website. Now, instead of simply having access to system performance across temperatures, the new tools asks for designers/installers to enter heating load info and location. This generates a heating load line across the range of winter temperatures for the unique project for which a designer is selecting. With the specific system’s capacity curves overlaid on load line, several important questions can be easily answered.

What does this help us quickly determine?

Simply put – the relationship between a system’s capacity and heating load at design temperature. Using “rated capacity” at 47F is not very useful as the chart demonstrates. This system may be called a three ton or 36 kbtu/hr, but at design temperature, 5F in this hypothetical case, it’s really a two ton or 24 kBtu/hr. This is a very important distinction.

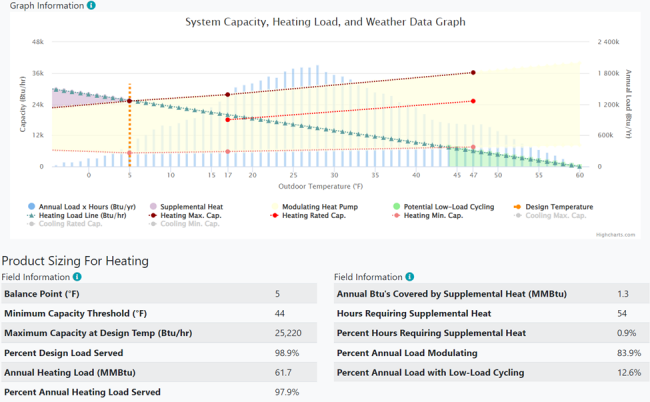

What about if you want to see how this system is able to turn down during mild temperatures to minimize short cycling? In this case, cycling is minimal…green shading represents a small amount of time that this system will cycle…approximately 12 percent of the annual load

If we want to visualize when the heat pump is modulating during the heating season, we can look at the yellow shaded zone to see if the load lives inside that zone… 84 percent of the annual load falls in the modulating zone for this example.

Another nice feature is the ability to see how much of the annual heating energy takes place at various temperatures. The blue bars suggest the bulk of heating energy is needed between 20-35F, a range where this particular system will be modulating.

The tool generates a series of calculations that are helpful in characterizing system performance under for a specific set of project needs.

In addition to this product view functionality, users can search the product list to find particular products that maximize different variables that a designer might want to prioritize.

We recommend new users refer to the user guide – which can be found on the landing page – for some additional guidance and definitions. Please remember that this tool is for preliminary product selection planning only. Additional considerations and practices are still necessary and highly recommended.

Here’s are some helpful links:

- Cold Climate Air Source Heat Pump Product List (including sizing tools)

- User Guide: Cold Climate Heat Pump Sizing Support Tools

- Cold Climate Air Source Heat Pump Specification

While we already have a running list of possible enhancements to the tools, we’ll be looking to user experiences to guide future evolutions. Don’t be afraid to let us know how we can make this tool more useful to you and the market. Send ideas to ccASHP@neep.org.