By David Lis | Fri, January 31, 25

A collaborative of energy efficiency organizations and HVAC manufacturer representatives, convened by NEEP, recently completed new research on the “representativeness” of energy efficiency ratings for air-source heat pumps. In other words, how well do the ratings and test procedures we use to measure product efficiency in the lab match with performance in the field.

The research found that a “load-based” test procedure produced results more representative of system capabilities than the current industry test procedure that uses locked or “fixed” compressor speeds. While the research relied on results of only five heat pump systems, the systems were carefully tested in the lab and in the field. The results suggest that improvements to our current test procedures are possible and further research to expand on and corroborate the findings is warranted. Here, we unpack the importance of test procedures from the lab, summarize study findings, and tee-up opportunities for further research.

The Importance of Test Procedures from the Lab

The study was part of an effort to modernize lab-based test procedures and energy efficiency ratings used to predict the in-field efficiency of heat pumps and to ensure that ratings are representative of in-field efficiency. Energy efficiency ratings for appliances and equipment are a foundational tool for market transformation. Lab-based performance ratings provide critical information to the market for development, sales, and selection of heat pump systems. It is essential that they represent real-world performance. A disconnect between a lab-based efficiency rating and in-field performance would distort the market for energy efficiency and compromise the trust that program implementers, contractors, and policymakers have in how the equipment they install will perform.

Increasingly, we see installation of variable speed air-source heat pumps that rely on proprietary controls to manage the systems’ operation and efficiency. Existing test procedures, which determine performance under fixed speed conditions, have come under increased scrutiny because of the disconnect between artificially “locked” operation and operation under a system’s own controls. Energy efficiency programs also have a keen interest in representative performance ratings to ensure incentive investments achieve the expected savings. Representative test procedures and ratings enable the adoption of high-efficiency heat pumps across North America, commonly identified as an essential step toward decarbonizing homes and businesses.

Controlled Lab and Field Study of 5 Heat Pumps Shows Room to Improve Ratings

To explore the representativeness of current (DOE M1/AHRI 210/240) and emerging ASHP test procedures (Canadian Standards Association’s SPE-07 ), NEEP facilitated a collaborative of several organizations to advise and fund a two-phase study. Funding partners included NEEP, Air-Conditioning, Heating and Refrigeration Institute (AHRI), BC Hydro, CLASP, ComEd, New York State Energy Research and Development Authority (NYSERDA), Natural Resources Canada (NRCan), Northwest Energy Efficiency Alliance (NEEA), Pacific Gas & Electric (PG&E), Southern Cal Edison, and Xcel Energy. Teams from DNV, University of Nebraska Lincoln, and UL conducted the research.

The study’s reports - Residential Heat Pump Efficiency Rating Representativeness Project Phase 1 and Residential Heat Pump Efficiency Rating Representativeness Project Phase 2 - capture the results of the controlled lab and in-field study of five heat pump systems.

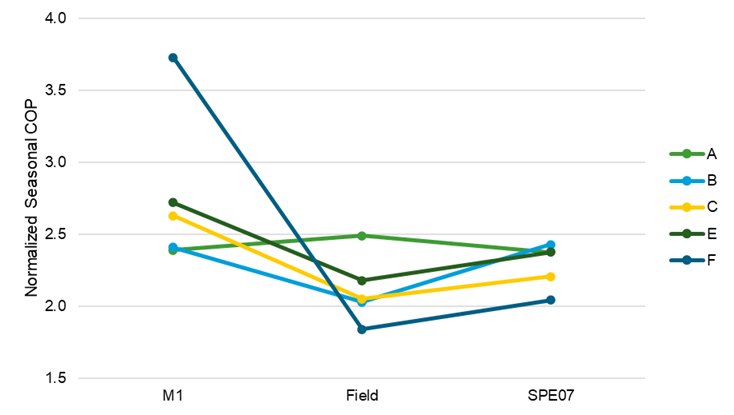

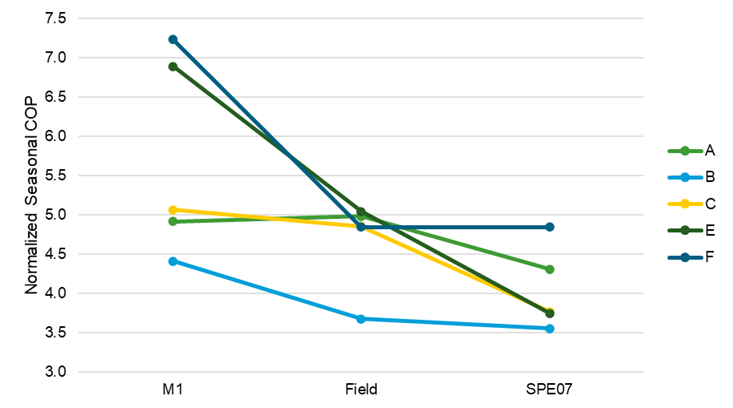

The results of the five-system study can be visualized in the following charts. Efficiency for systems A-F were measured in three ways. “Field” are the results that were measured during uncontrolled field operation. We considered these values the most in line with a systems’ true capabilities and efficiency. The other two measurements were based on lab-based performance testing. M1 are the results of the current test procedure and rating methodology, and SPE07 are the results according to the load-based test procedure. The closer the lab test results are to the “field”-based results the more “representative” those lab test would be considered. So, in this instance relatively flat lines would reflect lab tests that produce representative results.

Figure 1: Heating Efficiency Values from Field and Lab Data – Normalized to Cold/Dry Climate

Figure 2: Cooling Efficiency Values from Field and Lab Data – Normalized to Mixed Climate

When the results were compiled across the five systems, today’s efficiency ratings (M1) for heat pumps inflated actual performance (by +22% for cooling efficiency and by +36% for heating efficiency). Emerging load-based test ratings (SPE-07) generally underestimated cooling efficiency (-13%) and generally inflated heating performance compared to actual (+10%).

The results suggest improvements should be made to the current test procedure/rating process so that efficiency ratings can provide more representative information to the market. SPE07’s load-based procedure offers potential opportunities to enhance or overhaul the current industry procedures. All stakeholders agree that lab-based efficiency ratings for heat pumps must balance repeatability, reproducibility, and representativeness with test burden.

More Testing and Research Necessary

While more exploration of SPE-07 or other load-based testing is warranted to confirm the results seen in this study, preliminary data from this study has already influenced the next M1 test procedure update. In the summer of 2023, AHRI convened members and efficiency stakeholders to develop updates to the AHRI 210/240 test procedure that DOE uses by reference. Specifically, the load equation and climate-based bin hours definition from the SPE-07 standard were adopted as well as a controls verification test that can be used to ensure the part load capabilities under a system’s own controls. Some of these changes will take effect as soon as this year.

NEEP will work with project partners and our Heating Electrification Initiative partners to communicate these results to the market and regulatory bodies such as DOE in an effort to improve the way we test and rate energy efficiency for air-source heat pumps. State, regional and national efforts to promote high efficiency heat pumps towards market transformation of the HVAC market would benefit from more representative efficiency ratings.

About NEEP’s Heating Electrification Initiative

NEEP’s Heating Electrification Initiative works collaboratively with regional and national stakeholders to accelerate the adoption of high-efficiency air-source heat pumps and other energy-efficient solutions for heating our region’s homes and buildings. We develop research, strategies, tools and resources to address market barriers that might prevent further uptake.