By Arjun Mehra | Tue, November 24, 20

For newcomers in the HVAC industry, the terms used to describe heating and cooling technologies can feel like a jumble of acronyms, all describing the same principle with slight variations. It wasn’t until I attended NEEP’s ASHP and Market Transformation Workshop during my internship that I gained a deeper understanding of two important acronyms in the industry: air source heat pumps (ASHP) and variable refrigerant flow (VRF). These acronyms represent two technologies at the forefront of the heating electrification movement sweeping across the Northeast, Mid-Atlantic, and beyond.

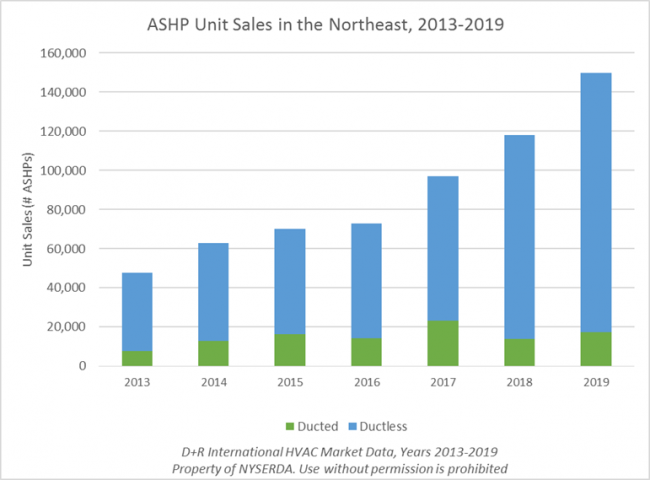

ASHPs and VRFs are gaining momentum in their adoption, owing to the environmental and efficiency benefits they offer. ASHP and VRF systems are performing competitively with conventional residential and commercial HVAC types, and since 2013, sales in the Northeast have tripled.

Behind the scenes, however, I learned that these advanced technologies face a variety of nuanced challenges that require concerted discussion and action to overcome. If not installed correctly, and/or designed properly for the dwelling they will serve, heat pumps present serious operational issues that sour consumer faith in the technology. Scaling up implementation of heat pumps is a welcomed occurrence but only if done right, and as the title of the workshop insists, we’ve got to be careful about scaling up quickly.

To discuss and better understand these challenges, NEEP assembled expert panels of program administrators and system engineers to compare best practices and share market insights. The rapid development of these technologies makes it essential to return to this discussion often to find the right balance between driving system adoption and maintaining customer satisfaction.

Scaling up: Program Management Strategies

Around the Northeast, program administrators are pushing their goals for decarbonization and electrification, and with it, are looking for ways to implement more ASHP and VRF systems. Some programs are offering several different incentives (mainly in the form of rebates) to encourage adoption of all types of heat pumps. Panelist Will Xia, Program Manager at Con Edison in New York, explained that their programs focus on offering flexible incentives so that customers can have the choice to pick their own systems. Meanwhile, Kyle Svendsen, Senior Energy Efficiency Consultant at Eversource in Massachusetts, presented their two-tiered approach: (1) standard rebates, and (2) a fuel optimization program. The difference in savings is nearly $1000, but the fuel switching component requires a significant investment from the consumer and helps to address that. While flexibility is a key factor for these programs, their main focus is on increasing install volume of heat pumps to meet utility or state targets. The question is: what else needs to be in place for heat pumps to satisfy the needs of both the programs and the consumer?

The big topic of discussion around quality assurance was weatherization measures. Weatherization is a strategy that promotes heat pump performance by improving the thermal efficiency of the building in which it goes. Panelists cited concerns over diminishing returns with increasing investment in efficiency measures like weatherization, and Kyle Svendsen of Eversource noted that with their current targets, weatherization can create an additional barrier to entry for their heat pump program. Andy Meyer of Efficiency Maine expressed that they try to focus on the EE measures that yield the best results. Thus far programs have tried avoiding pitting EE measures against each other, and as a result, most programs have weatherization incentives and programs separate from ASHP and VRF systems.

While program administrators have found successful ways to integrate ASHP and VRF systems into their programs, there are still several challenges related to system design and install to be tackled in order to guarantee quality. The design and install process has played, and will continue to play, a key role in ensuring customer satisfaction.

Quality Assurance & Challenges

Bring in the quality experts. When the discussion turned to quality assurance, the system design panelists brought weatherization to the front. From a design perspective, weatherization is a differentiator in the sales process and critical for energy efficiency. A tighter thermal shell implies smaller and less-expensive heat pumps required to heat and cool the building. Panelist Mike Cappuccio, Owner and President of N.E.T.R., Inc., recommended that HVAC contractors align their company with a good home auditor who does weatherization. Inside salespeople can book an energy audit for the customer and, in his experience, he’s found that homeowners are more responsive to an energy auditor than an HVAC salesperson.

Oversizing is another design issue that is prevalent in both ASHP and VRF systems. This is often the result of unrealistic assumptions muddling the load calculations or offering greater incentives for larger systems. This phenomenon highlights the importance of having experienced home auditors who can provide the correct information needed for load calculations to size the system. It is also important for program administrators to educate customers that the savings reductions caused by oversizing offsets the higher incentives offered by the program.

There was much conversation around the newness and complexity of this technology, and because of it, many conventional HVAC contractors don’t have enough experience to provide quality installations every time. Inexperience can lead to the oversizing of systems, refrigerant leakage, and heating fluctuation issues to name a few. Jake Marin, HVAC Program Manager at Efficiency Vermont, says VRF systems remain a niche technology in his state and will remain that way until installers stamp out refrigerant leaks and other performance issues. At the same time, VRF contractors in other jurisdictions have been successfully installing systems in commercial buildings for years. Ultimately, lack of universal comprehension among installers hurts the reputation of the technology and holds back the industry as a whole.

Striking the Balance

In order to mitigate these issues and strike the install volume/quality balance, the first step is investing in contractor and installer training and awareness of ASHPs and VRFs. Fortunately, as discussed in the workshop, a lot of headway has been made in developing trainings and standardizing what’s already available. For example, the standard load calculation method ACCA Manual J is now a requirement for participation in some programs such as the NYS Clean Heat Program. Some programs have their own internal training systems for contractors, and others rely on certification programs.

Some states like Maine offer training scholarships to people involved in the industry. Furthermore, utility providers such as Con Edison implement statewide checklists for installation technicians. With some contractors experiencing downtime from the COVID-19 pandemic, there is an opportunity to accelerate contractor training efforts. Organizations like the Building Performance Association (BPA) have already made decisions around that.

Lastly, since the requirements of every install vary, installer experience is crucial in guaranteeing quality for mass installs. This piece will likely improve over time as heat pumps become the preferred HVAC option. Solving the puzzle will come from customer interactions that teach technicians comfort and functionality of the system is as important as the performance. Programs are already facilitating this; once contractors have completed the requisite training and performed a few successful installs, they are added to the program’s list of verified contractors that gets shared with customers. This ensures that customers have access to experienced contractors vetted by the program itself. Measures like this add another layer of verification to installers and provide incentives for them to maintain quality.

The NEEP workshop was successful in creating a space for expert stakeholders across the industry to come together and discuss the state of the ASHP and VRF markets. The different perspectives offered by program and supply chain panelists provided insight into the obstacles faced by the industry and helped identify opportunities for growth and collaboration. Maintaining the ideal balance between install volume and customer satisfaction will require education, awareness, transparency, and collaboration on all levels of the industry, and workshops like this are essential to realize the full potential of this technology.