By Dave Hewitt | Mon, April 29, 19

Energy and Environmental Economics (E3), a California based consultancy, has taken a detailed look at the economics of electrification on behalf of three California utilities. The results show that: “All new construction homes and the majority (84 percent) of existing single-family homes with A/C would save by going all-electric.” For homes with air conditioning, the efficiency of advanced heat pumps leads to bill savings that outweigh higher initial costs.

The study, Residential Building Electrification in California, also indicates that greenhouse gas reductions would be immediate for the electrified homes at the current mix of renewable and fossil-based electricity generation in California. Greenhouse gases would continue to decrease as the generation mix becomes more renewable in the future.

In retrofitting existing homes, there is a general concern that heat pumps will have higher first costs. However, when central air conditioning is present, moving to a heat pump may offer immediate savings to consumers. As the study indicates:

“High capital costs of electric heat pump retrofits in existing homes are often perceived as a barrier to electrification, but this assumption was not borne out for homes that are otherwise already upgrading the air conditioning system. While HVAC systems are highly capital-intensive in general, in most cases we found capital cost savings when replacing the combination of an air conditioner and a gas furnace with a standalone heat pump HVAC unit.”

The study also looks at water heating, cooking, and dryer fuel switching. In water heating, the study finds that: “Heat pump water heaters in existing homes showed bill savings compared to gas storage water heaters, but they had significantly higher capital costs. Very high efficiency water heaters and smart appliances with flexible schedules (especially with compatible rate design) would yield improved bill savings in new construction, while low cost, retrofit-ready models could help with existing homes.”

Dryers generally had higher life cycle costs for electric rather than gas, as did cooking. However, for cooking, the report very nicely summarizes the potential move to induction cooking as follows:

“Currently available induction stoves have higher capital costs than gas stoves in the U.S., but that is likely a function of the current market targeting induction as a high-end option. Low-cost portable induction burners are available in today’s market, and induction stoves are cheaper in other countries, such as China, where they are more common. Induction may have non-economic advantages such as more precise cooking temperatures, easier cleanup, and superior health and safety profiles, but most customers remain unfamiliar with them relative to conventional electric resistance stoves.”

The report also briefly considers impacts of gas infrastructure and rate design on the outcomes. Readers interested in those topics should refer to the full document to better understand the study’s assumptions, parameters, and conclusions.

We Need Better Information Throughout the Country

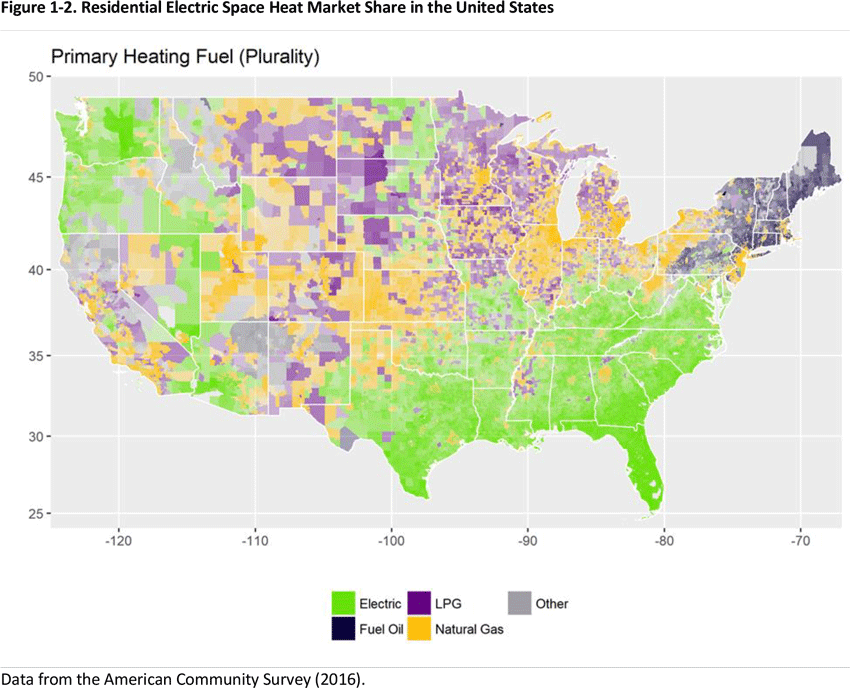

Regional reviews of electrification economics are an important piece of analysis that more cities, states, and regions need to undertake. Economics can change with energy prices, residential construction costs, climate, and other factors. However, the presence of whole-house air conditioning is a major factor. A single HVAC system – a heat pump – can replace two systems (a warm air fossil fuel furnace and a whole house air conditioner). That simple change is a big boost to the economics.

In many warmer climates, heat pumps are currently installed in about half of residential new construction. The relatively recent advent of cold climate ASHPs extends the climate zone where this one-for-two switch can occur, expanding to areas where heat pumps have been less utilized in the past. Where central air conditioning is already a common amenity in the marketplace, the economics of heat pumps tend to look more favorable. NEEP rates current generation heat pumps “cold climate” based on performance efficiency down to five degrees Fahrenheit, which moves the climate zone for application decidedly northward.

Fifteen years ago I replaced my (no longer functional) central AC and gas furnace (with a cast iron heat exchanger – how did that work?) with the up-to-date replacement choices of the time. I debated a heat pump rather than the AC, but still would have needed the gas furnace (or more electric resistance heat than I could stand) for cooler weather. Today, one piece of equipment can clearly do both jobs. If only my local HVAC dealer knew what a cold-climate ASHP is, I would be golden if my space heating equipment quit on me. Educating my local dealer is a relatively small hurdle for me to jump, but I don’t accurately represent the majority of customers. Every day somebody in my city makes a similar decision, and the HVAC dealer and customer miss a chance to reduce greenhouse gases and potentially reduce consumer costs for another 20 years. There is a lot of educating to do.

Education around ASHPs needs to target policy makers, utilities, HVAC firms, and the broader public. The technology and economics have changed. The imperative around climate change is stronger. The various cities, states, and regions in the country need to better understand how these changes impact their citizens and businesses and how these technologies can help meet climate goals. We need to begin enabling the market to work better to bring these new options forward. But first, we need to better understand these new options, their best applications, their economics, and all of their benefits. Then, it will be easier to pick up the pace of moving the market to support decarbonization.

This blog is part of Building Decarb Central, a series of blogs and other resources aimed at providing a constant flow of information on building decarbonization. Be sure to check out our web portal for more stories, resources, and information.